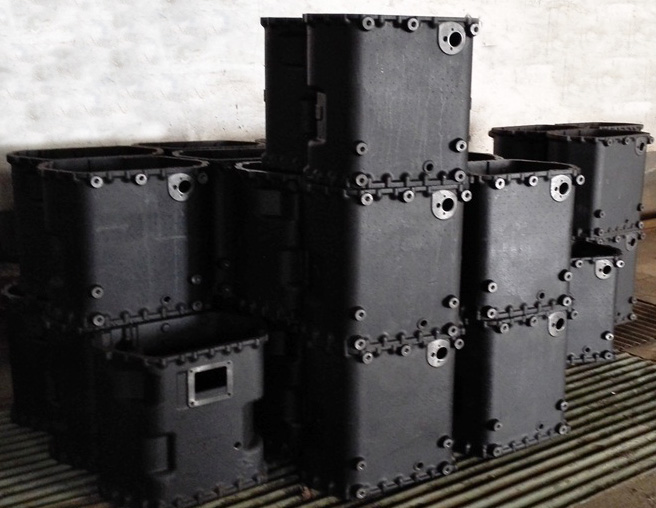

Steel Vacuum Casting Company ti Cina jeung OEM Adat jeung CNC Machining Services.

Beusi tuang mangrupikeun paduan tuang beusi-karbon sareng unsur-unsur sanés anu didamel ku cara ngalebur beusi babi, besi tua, sareng tambahan sanésna. Pikeun diferensiasi tina baja jeung baja tuang, beusi tuang dihartikeun salaku alloy tuang kalayan eusi karbon (min 2.03%) nu ensures solidifikasi fase ahir ku transformasi eutektik.

Gumantung kana spésifikasi kimiawi, beusi tuang tiasa non-alloyed atanapi alloyed. Kisaran beusi alloyed leuwih lega, sarta ngandung boh jumlah luhur komponén umum, kayaning silikon jeung mangan, atawa tambahan husus, kayaning nikel, kromium, aluminium, molybdenum, tungsten, tambaga, vanadium, titanium, tambah. batur. Sacara umum, beusi tuang bisa dibagi kana beusi abu, beusi ductile (beusi nodular), beusi tuang bodas, beusi grafit compacted jeung beusi matak malleable.

Bahan Baku Sadia pikeunVakum Casting

• Beusi Gray: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Beusi ulet atawa Beusi Nodular: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Baja Karbon: Karbon rendah, karbon sedeng jeung baja karbon tinggi ti AISI 1020 nepi ka AISI 1060.

• Tuang Steel alloy: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo ... jsb on pamundut.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L jeung kelas stainless steel séjén.

• Kuningan & Tambaga.

• Bahan séjén sarta Standar on pamundut

Prosedur Produksi utama vakum casting

Pola & Desain Alat → Nyieun Pola → Prosés Molding → Analisis Komposisi Kimia → Lebur & Tuang → Beberesih, Grinding & Shot Blasting → Post Processing atawa Bungkusan pikeun Kiriman

Keusik Casting Kamampuh Inspection

• Spectrographic jeung analisis kuantitatif manual

• analisis Metallographic

• Brinell, Rockwell na Vickers inspeksi karasa

• analisis sipat mékanis

• Uji dampak suhu lemah sareng normal

• inspeksi kabersihan

• UT, MT jeung inspeksi RT

Prosés Post-Casting

• Deburring & beberesih

• Shot Blasting / Keusik Peening

• perlakuan panas: Normalisasi, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Andonizing, Electroplating, Hot Séng Plating, Séng Plating, Nikel Plating, Polishing, Electro-Polish, Lukisan, GeoMet, Zintec

• Machining: Balik, panggilingan, Lathing, pangeboran, Honing, grinding,

Sarat Commerial Umum

• Aliran kerja utama: Inquiry & Quotation → Confirming Rincian / Cost Reduction Proposal → Tooling Development → Trial Casting → Sampel Persetujuan → Trial Order → Mass Production → Continuous Order Proceeding

• waktos kalungguhan: Diperkirakeun 15-25 poé pikeun ngembangkeun tooling sarta diperkirakeun 20 poé pikeun produksi masal.

• Sarat pamayaran: Bisa disawalakeun.

• métode pamayaran: T / T, L / C, West Union, Paypal.