OEM custom stainless steel casting awak pompa kalawanjasa mesin CNCsarta jasa perlakuan panas ti Cina casting foundry.

Stainless steel boga eusi Cr minimum 11,5%, sarta elemen alloy lianna kayaning Ni jeung Mo, sahingga leuwih tahan ka lingkungan cair corrosive jeung ka oksidasi. Cai mibanda kinerja tahan korosi tinggi jeung tahan ngagem, nyadiakeun machinability alus teuing, sarta ogé dipikawanoh pikeun penampilan estetika na.Castings investasi stainless steel"tahan korosi" nalika dianggo dina lingkungan cair sareng uap sahandapeun 1200 ° F (650 ° C) sareng "tahan panas" nalika dianggo di luhur suhu ieu.

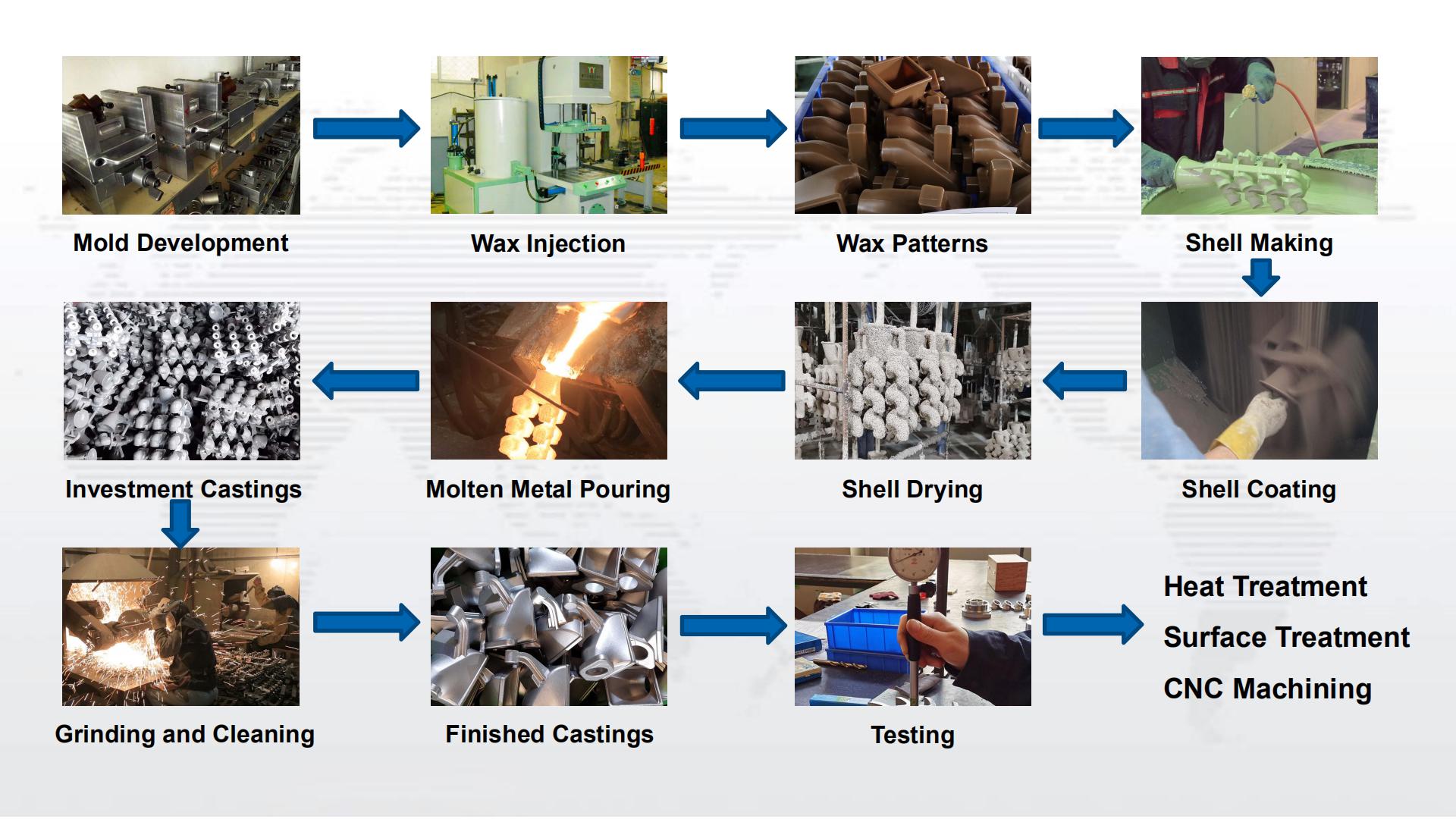

Prosés casting sol silika nyaéta utamaprosés casting investasi bajatina RMC investasi casting foundry. Kami parantos ngembangkeun téknologi anyar bahan napel pikeun ngahontal bahan napel anu langkung ekonomis sareng efektif pikeun ngawangun cangkang slurry. Ieu tren overwhelming yén prosés casting sol Silika ngagantikeun prosés kaca cai inferior kasar, utamana pikeun casting stainless steel sartacasting baja alloy. Di sagigireun bahan molding innovated, prosés casting sol silika ogé geus innovated mun loba steadier na kirang panas ngembangna.

| Bahan pikeun Prosés Casting Investasi di RMC Foundry

| |||

| Kategori | Kelas Cina | Kelas AS | Kelas Jérman |

| Ferritic stainless steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic stainless steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| stainless steel Austenitic | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 1.4406 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Présipitasi Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Luhur Bungbulang Baja | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Pakakas Baja | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Baja Tahan Panas | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nikel-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| alumunium Paduan | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Alloy tambaga | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Alloy basis kobalt | UMC50, 670, Kelas 31 | 2.4778 | |