matak customproduk casting investasi stainless steel duplexti Cina tuang foundry kalawan machining, perlakuan panas, sarta jasa perlakuan permukaan.

RMC matakprecision matak bagian bajanu konsistén minuhan atawa ngaleuwihan ekspektasi customer. Leungit lilin investasi casting ngamungkinkeun urang pikeun ngahasilkeun bagian logam sakumaha leutik sapuluh gram sarta saloba puluhan kilogram, dina rupa-rupa alloy ferrous jeung non-ferrous sarta kalawan akurasi diménsi luar biasa.

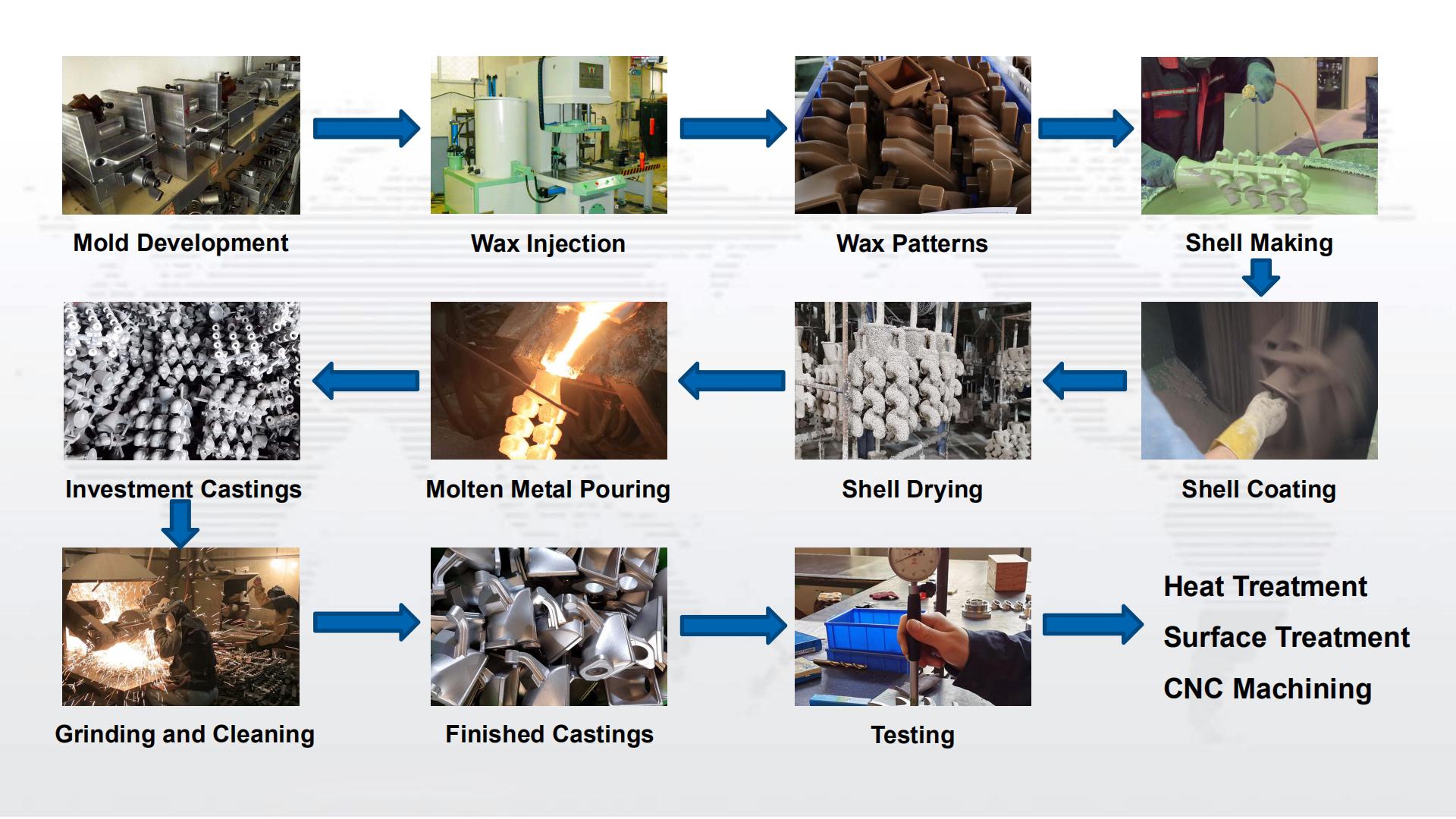

Prosés casting lilin leungit ngahasilkeun deukeut-net-bentuk precision bagian logam anu mindeng merlukeun saeutik atawa euweuh machining tambahan. Hasilna hasilna ogé langkung saé tibatan anu tiasa dihontal ku prosés anu sanés. Kakuatan sareng daya tahan bagian casting ngajantenkeun diri idéal pikeun aplikasi tahan-tahan anu luhur anu peryogi jutaan siklus.

Duplex Stainless Steel (DSS) nujul kana stainless steel kalawan ferrite na austenite unggal akuntansi pikeun ngeunaan 50%. Sacara umum, eusi fase kirang kedah sahenteuna 30%. Dina kasus eusi C low, eusi Cr nyaéta 18% nepi ka 28%, sarta eusi Ni nyaéta 3% nepi ka 10%. Sababaraha baja stainless duplex ogé ngandung unsur paduan sapertos Mo, Cu, Nb, Ti, sareng N.

Kelas sadia tina stainless steel duplex di RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A, A 890 3A, A 85, A 90 A A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS boga ciri tina stainless steel austenitic jeung ferritic. Dibandingkeun jeung ferrite, éta boga plasticity luhur sarta ductility, euweuh brittleness suhu kamar, sarta nyata ningkat lalawanan korosi intergranular jeung kinerja las, bari tetep ngajaga brittleness, konduktivitas termal tinggi, sarta superplasticity sakumaha ferrite stainless steel. Dibandingkeun jeung stainless steel austenitic, DSS boga kakuatan tinggi na nyata ningkat lalawanan ka korosi intergranular sarta korosi stress klorida. Duplex stainless steel gaduh résistansi korosi pitting anu saé sareng ogé baja tahan karat nikel.

| Sarua Kelas tina Stainless Steel | |||||||

| GOLONGAN | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensit jeung Ferritic Stainless Steel | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 KrAl 13 | 405 S 17 | - | F.3111 | X6 KrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Stainless Steel Austenitic | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Steel | S32750 | 1.4410 | X 2 KrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Logam Ferrous jeung Logam Non-ferrous pikeunInvestasi Casting, Prosés Casting Lilin Leungit:

• Beusi Gray: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Beusi ulet atawa Beusi Nodular: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Karbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Steel alloy: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo ... jsb on pamundut.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 jeung kelas stainless steel séjén.

• Kuningan, Beureum Tambaga, Perunggu atawa logam alloy dumasar-Tambaga séjén: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Bahan lianna numutkeun sarat unik anjeun atanapi numutkeun standar ASTM, SAE, AISI, ACI, DIN, EN, ISO, sareng GB

▶ Kamampuhan tinaInvestasi Casting Foundry

• Ukuran Max: 1.000 mm × 800 mm × 500 mm

• Beurat Range: 0,5 kg - 100 kg

• Kamampuh taunan: 2.000 ton

• Bahan Bond pikeun Wangunan Shell: Silika Sol, Cai Kaca jeung campuran maranéhna.

| Jasa | Katerangan |

| Jasa Perlakuan permukaan | Palapis bubuk, Anodization, Éléktrofotésis, Chrome Plating, Lukisan, Keusik blasting, nikel Plating, Séng Plating, Blacking, Polishing, Bluing, Geormet, Zintek, jsb. |

| CNC Precision Machining Services | Lathing, panggilingan, péngkolan, Honing, pangeboran, boring, ngetok, Kawat éléktroda motong, grinding ... jsb. |

| Inspeksi sareng Kontrol Kualitas | Spéktrum Analyzer, CMM, Teu karasa Tester, Tensile Kakuatan Tester, ngahasilkeun Strentgh Testor, Sealing Tekanan Tester, Karbon Walirang Analyzer, Metalurgi Mikroskopi, Pencét Force Tester ... jsb. |